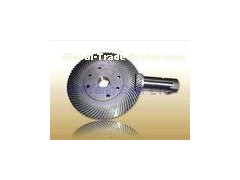

Custom Helical Bevel Gears , Ground Tooth Spiral Bevel Gear Hobbing Process

Customized Helical Cast Steel Bevel Gears / ground tooth spiral bevel gear is a rotating machine part with cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. It includes spur gear, helical gear, skew gear, bevel gear, spiral bevel gear and so on. It is widely used for all kinds of machinery equipment.

| Material | C45# steel, 40Cr, 20CrMnTi, 20Mn, alloy Steel, 20MnTi, Cast Iron etc. |

| Process | Forging, Machining, Hobbing, Milling, Shaping, Shaving, Grinding, Heat treatment. |

| Heat treatment | High frequency quenching, heat treatment, hardened teeth |

| Surface treatment | Blacking, galvanization, chroming, electrophoresis, or customer requirement |

| HrC | 20CrMnTi - carburization -(58~62) C45# steel - high frequency -(40~45) |

| Performance | High precision, high wear resistance, low noise, smooth and steady, high strength |

| Model number | Standard or nonstandard |

| Application | Tractor, feeding machinery, harvester, mining machinery etc. |

Customized Helical Cast Steel Bevel Gears / ground tooth spiral bevel gear Advantage

1. The geographical position advantage: located in sprocket town, professionally produce every kind of gear and gear rack.